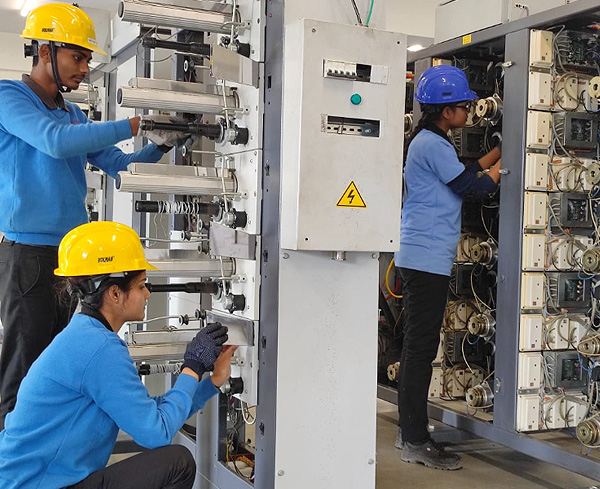

MTTC Project has been envisioned with prime objective to develop trained manpower for the internal requirement of LCL manufacturing facilities at Chaubepur & Panki. While designing the MTTC Project, need – assessment survey was done at various departments of both manufacturing facilities. Accordingly, the training courses have been designed in line with German dual VET model. MTTC started it’s training operation March 2019. The 04 specialized training courses on "Precision Machinist", "Sheet Metal Fabrication", "Assembly Fitter", "Electrical Assembly Fitter" are conducted at MTTC to cater to the need of requirement from LCL’s manufacturing units of Chaubepur and Panki, Kanpur.